The History of the Loom

Looms are devices used for weaving fabrics, and their history dates back thousands of years. It is interesting to note that the invention of looms happened independently in different places and time periods.

The earliest known looms were found in Georgia in the Caucasus region and date back to around 30,000 BCE. According to a report by Science Magazine, "the discovery pushes back the earliest known use of woven fibers by more than 8,000 years." The researchers who made this discovery also suggest that the weaving technology was invented independently in different places around the world, including Europe, Asia, and the Americas.

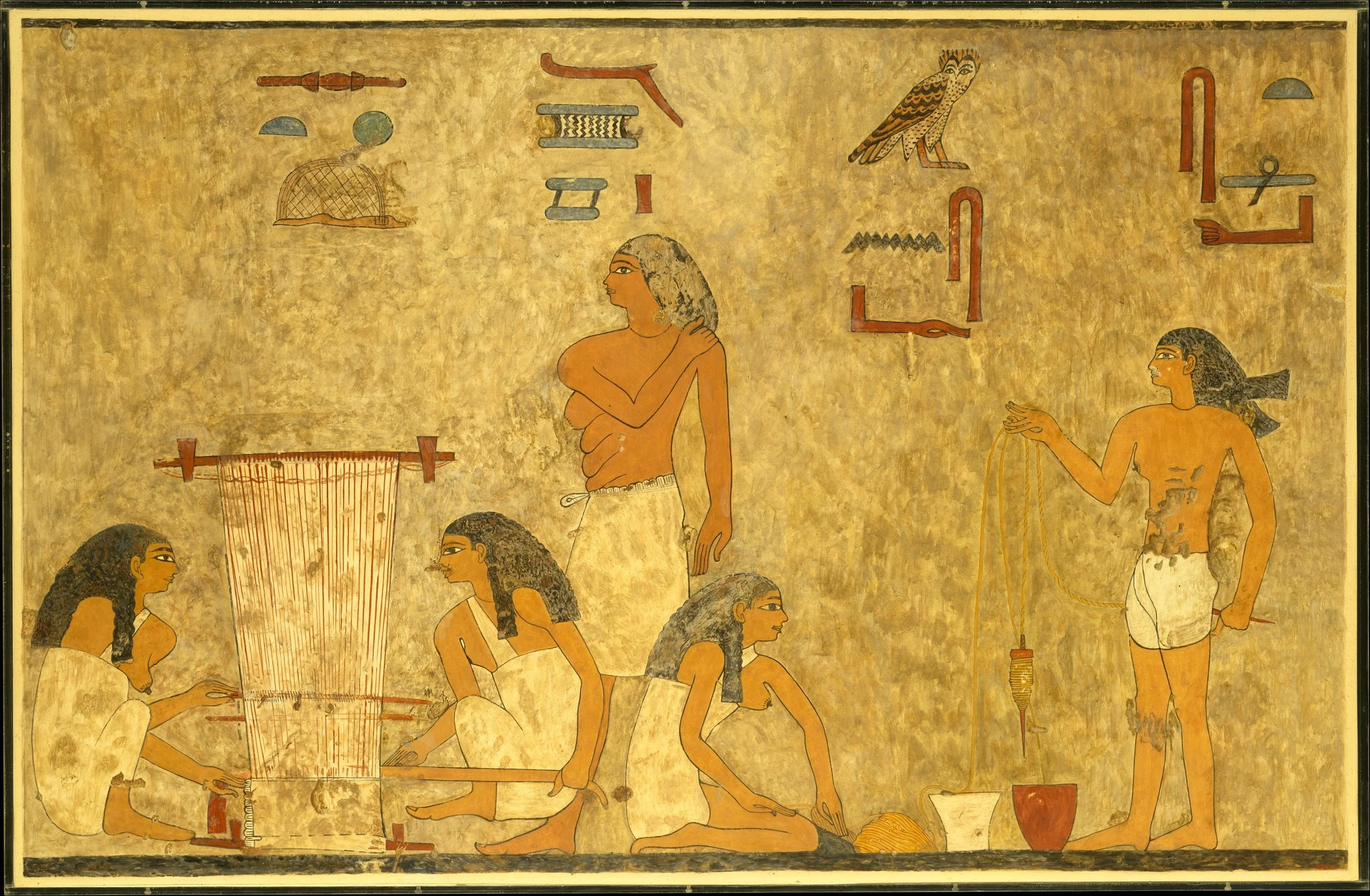

Egyptian strapback looms. Carving found in the tomb of Khnumhotep II, 2000 BCE.

In ancient Egypt, looms were used to weave linen fabrics. The warp-weighted loom was the most common type used in ancient Egypt, and it was powered by the weaver's feet. This type of loom was also used in ancient Greece, where it was known as the Hellenistic loom.

In China, the backstrap loom was used to weave silk fabrics. According to the book "Silk: Trade and Exchange along the Silk Roads between Rome and China in Antiquity" by Berit Hildebrandt, "Chinese tradition holds that the invention of the backstrap loom dates back to the Yellow Emperor, who reigned around 2600 BCE."

Diagram of an unearthed Chinese loom from around 100 BCE.

The drawloom, a type of loom that uses foot pedals to enable weaves to make intricate aptterns, was probably invented in China in the 5th century BCE, with the earliest drawloom found dated around 100 BC, and later introduced to India, Persia, and the Islamic world.

Before the drawloom, the backstrop was used, pictured in the Egyptian image. A drawloom,, however, is a much more complicated machine.

The drawloom reached Europe in the 800s and took its time to matriculate through the continent, and really took off in the 1500s. It soon became a significant technological innovation in the history of weaving, and it had a profound impact on the textile industry in Europe. It allowed weavers to create textiles that were more intricate and beautiful than ever before, and helped to establish the reputation of European textiles as the finest in the world.

During the days of the drawloom, a “draw-boy” used to sit on top of the loom and manually raise or lower different warp threads for every row of weaving. This was a slow and meticulous process that led inventors to search for a better system. Over a period of 75 years, several inventors attempted to improve the traditional draw loom.

Basile Bouchon was the first to improve the draw loom in 1725 by replacing bunches of looped strings with an endless band of perforated paper. In 1728, Jean-Baptiste Falcon used perforated cards that were manipulated by a draw-boy. In 1745, Jacques de Vaucanson combined both of these inventions by placing his machine where the pulley box had previously been. Finally, Joseph Marie Jacquard made the breakthrough by taking these inventions to the next level. He sped up the process and eliminated the need for a weaver's assistant.

Drawloom versus the jacquard attachment on top.

The jacquard loom was introduced in 1801 in Lyon, France and quickly spread to other parts of Europe. The loom used punched cards to control the weaving process, allowing for the creation of intricate patterns and designs with greater ease and efficiency than ever before. (SEE: The Jacquard Loom Riots)

The impact of the jacquard loom on the textile industry was immense. It allowed for the production of complex fabrics at a fraction of the time and cost it took to make them by hand. This increased efficiency and led to lower prices, making high-quality fabrics more accessible to a wider range of people.

The success of the jacquard loom in Europe spurred innovation in the textile industry. Suddenly, scores of inventors were modifyihng the jacquard loom, one-upping each other on designs. From being able to just modify the weft, William Horrocks invented a loom allowing the punchcards to control the warp and the weft. Richard Roberts then invented the Roberts loom which could automatically thread the jacquard loom in 1830.

These advancements, coupled with the industrialization of the textile industry, led to a period of unprecedented growth and prosperity in Europe throughout the 19th century.

It’s important to note that all of these types of looms are considered to be shuttle looms, because they use a shuttle to pass back and forth inside the “shed” that’s created by the warp threads rising and falling..

At the turn of the 20th century, many industries were looking for ways to increase productivity and efficiency. One of the ways they achieved this was by getting rid of shuttle looms, which were slow and required a lot of manual labor. In their place came a new generation of shuttle-less looms, including the Projectile Loom, Water-Jet Loom, and Air-Jet Loom.

Water jet loom

All of these shuttle-less looms have their advantages and disadvantages, and are still used in the textile industry today. While the Water-Jet Loom and Air-Jet Loom are still used, they have largely been replaced by the faster and more efficient Projectile Loom. Despite these technological advancements, shuttle looms are still used in some traditional weaving processes, such as selvedge denim and Harris Tweed.

We have seen how the ingenuity of humans led to the creation of various types of looms that were independently developed in different regions of the world, and how each innovation built upon the previous to make better fabrics. The invention of the drawloom, the jacquard loom, and the various modern looms, each with their own unique features, revolutionized the textile industry and paved the way for modern fabric manufacturing.

While we have explored the many advancements and changes that have occurred over the centuries, one thing remains constant: the loom is a testament to the power of human creativity and innovation.